This methodology uses a formula that determines the optimal time to reorder inventory. This system provides high control over high-value goods, but requires a large number of resources to continuously analyze the inventory levels of the other categories. Therefore, it is important to know which items are the best sellers, so that we have enough reserve stock available. Category “A” corresponds to high-value, low-quantity goods the category “B”, corresponds to goods of value and moderate quantities while the category “C” are goods of low value and large quantity.Įach category can be managed separately. This methodology uses three categories that represent inventory values and the importance of cost of goods. It is efficient to control simple Inventory Management processes, but, at the same time, more time consuming and prone to errors.

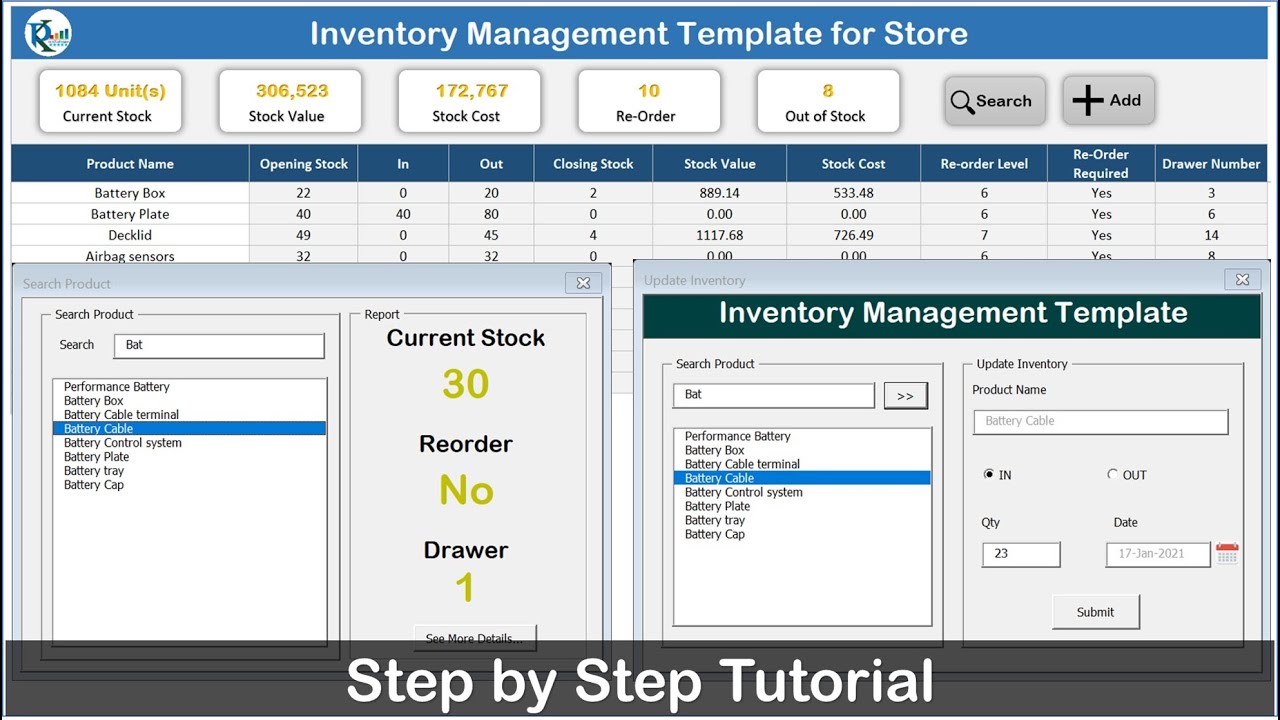

STOCK INVENTORY MANAGER MANUAL

It is essentially a manual methodology, but it also employs certain specific automated processes to define minimum stock levels. It consists of a regular analysis of available stocks, which is compared with projected future needs. It is the simplest methodology and generally the most attractive for small businesses. Some of the most common methodologies are the following: Stock review This allows us to have certain of when to order, and how much to order, in order not to fall into overstock expenses or lost sales. Most of the existing Inventory Management techniques are related to various planning and control tasks.

STOCK INVENTORY MANAGER REGISTRATION

This implies the need for an orderly, effective and efficient methodology to supervise aspects such as registration methods, control of rotation points and supply chain management, among others.

Both due to the need to maintain balance in the inventory of inputs, tools and / or final products, as well as the costs and risks associated with this complex task. Inventory is one of the most important assets in the strategic planning of any company. In order to achieve this objective, we need specialized digital tools, which provide more security, eliminate the margin of error and reduce the risks and associated costs. Managing the stock of products, supplies and tools in an agile, safe, effective and efficient way is essential for the success of companies in today’s competitive market.

0 kommentar(er)

0 kommentar(er)